Solvent extraction is a straightforward method to extract oil from oil-bearing materials. It involves treating the materials with a low-boiling-point solvent, such as normal hexane, known for its affinity to extract oils. The oil-bearing materials include sunflower, soybean, canola, rapeseed, cottonseed, mustard seed, rice bran, copra, linseed, kardi seed (safflower), neem, castor seed, mocha, salseed, and karinja. The solvent, with a boiling range of 67 degrees Celsius, absorbs the oils from the materials upon contact. The separated oils are then obtained through distillation.

Solvent Extraction involves the diffusion of solvent into the oil-bearing cells of raw materials, resulting in an oil-solvent solution. "Hexane" is chosen for its appropriateness, considering commercial viability, edibility of extracted products, and characteristics like its low boiling point. The process comprises three sections:

Efficient extraction requires optimal contact between the solvent and every oil-bearing cell in the material. Smooth preparation before the main extraction is crucial for this contact. Smaller material size enhances solvent penetration, but overly fine size hinders solvent percolation. Thus, an optimum size is essential for efficiency.

Material preparation methods vary based on oil content and physical properties, grouped as follows:

Prepared material is transported to the Main Extraction section via an NES Conveyor.

The prepared material is delivered to the Extraction plant via an NES conveyor through an NES air seal in the raw material receiver, with a control arrangement for the receiver's material level. The NES Extraction design allows for easy variation in the speed of material transportation.

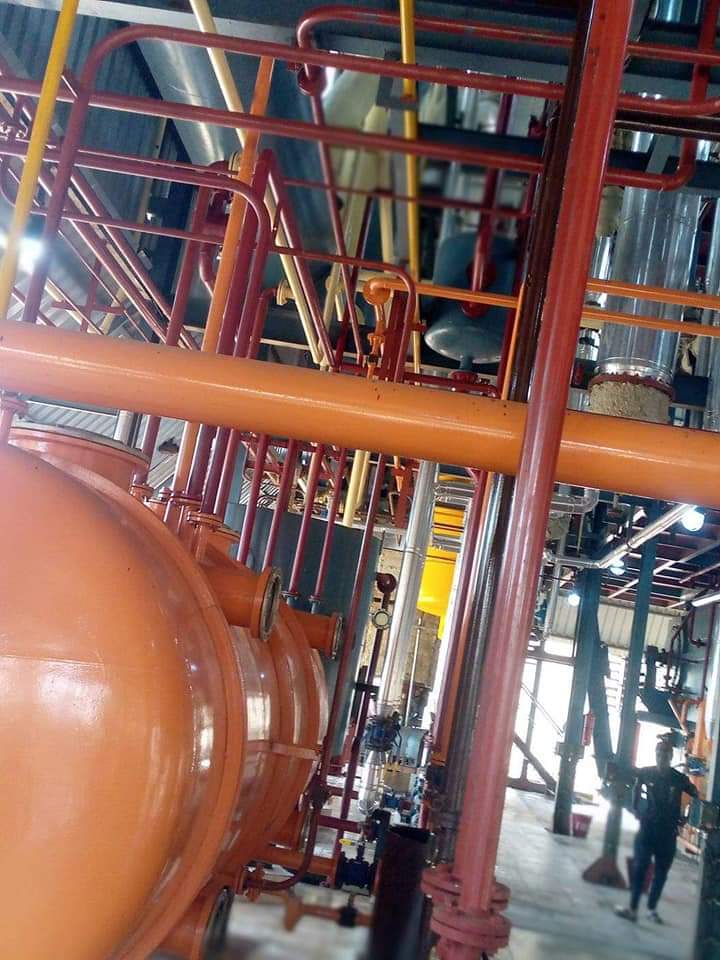

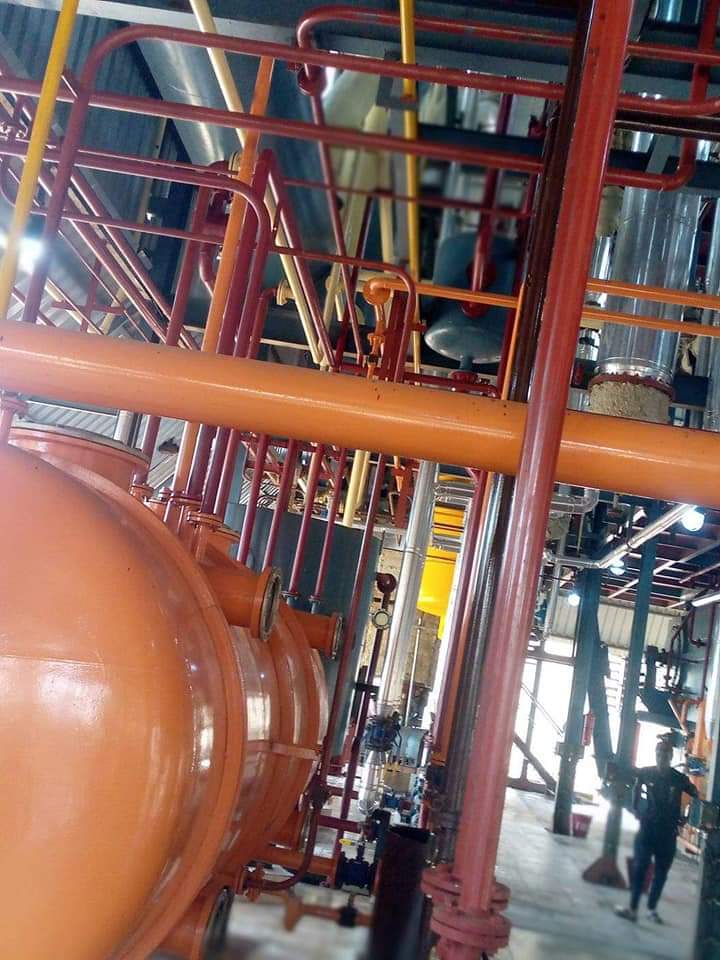

The solvent spraying chamber is a key component, equipped with numerous sprayers uniformly distributing solvent over the entire raw material bed. The chamber's length and breadth are designed to allow sufficient time for intimate contact, penetration, and saturation of the solvent into the raw material. For monitoring the spray distribution, the NES Extractor is equipped with light and sight viewing glasses.

The Main Extraction Section is further divided into subsections:

The extracted and desolventized meal is conveyed to the bagging section using a NES conveyor, which is equipped with cooling arrangements.

Ninja Engitech Solutions

Ninja Engitech is one of the leading manufacturer & supplier of Oil Extraction, Edible Oil Refinery, Oil Mill & Spare Parts in India & Abroad.